For the aerospace industry

Precision at all Altitudes

Modern aircraft engines are masterpieces of engineering. Requirements for performance and fuel efficiency are increasing constantly – as is the pressure for manufacturers and suppliers to shorten their development and production times. However, for such safety-critical parts, flawless accuracy is a must.

Coordinate measuring machines (CMMs), X-ray technology and 3D full-field measurements as well as the right software are crucial for such exacting tasks. ZEISS has solutions for every step of the production and the entire value chain, for example, when it comes to applications around turbine blades. Turbine blades are the workhorse of the modern aero engine. They operate in an extreme environment. Since its shape determines energy efficiency, airflow and thrust, any surface or dimensional imperfection can cause blade failure and ultimately engine failure.

Get the full picture:

ZEISS BOSELLO MAX

Fast, precise 2D X-ray technology for nondestructive testing (NDT) of turbine blades yields cost and time benefits. The ZEISS BOSELLO MAX X-ray system visualizes internal structures and detects inclusions and irregularities. It effortlessly x-rays dense materials such as Inconel or similar alloys. Thus, even the smallest defects are identified and remedied at an early stage.

The system meets the strict specifications and international standards of the aerospace industry. Thanks to its robust design, ZEISS BOSELLO MAX is perfect for use in the production environment.

Inspection with 3D measuring machine ATOS ScanBox BPS

The ATOS ScanBox BPS 3D measuring machine combines the speed and accuracy of ATOS ScanBox and the ATOS 5 for Airfoil sensor (dedicated for intricate airfoils) with the autonomy of the “BPS”, which stands for batch processing system. This standardized measuring machine provides a fully automated digitization of batches of up to 80 turbine blades in succession. Each part takes less than three minutes and is automatically loaded by the BPS system. The generated high-resolution mesh is a digital twin of the real part. The GOM Blade Inspect software automatically delivers the traditional airfoil inspections as well as full-field evaluation between the actual 3D coordinates and the CAD data.

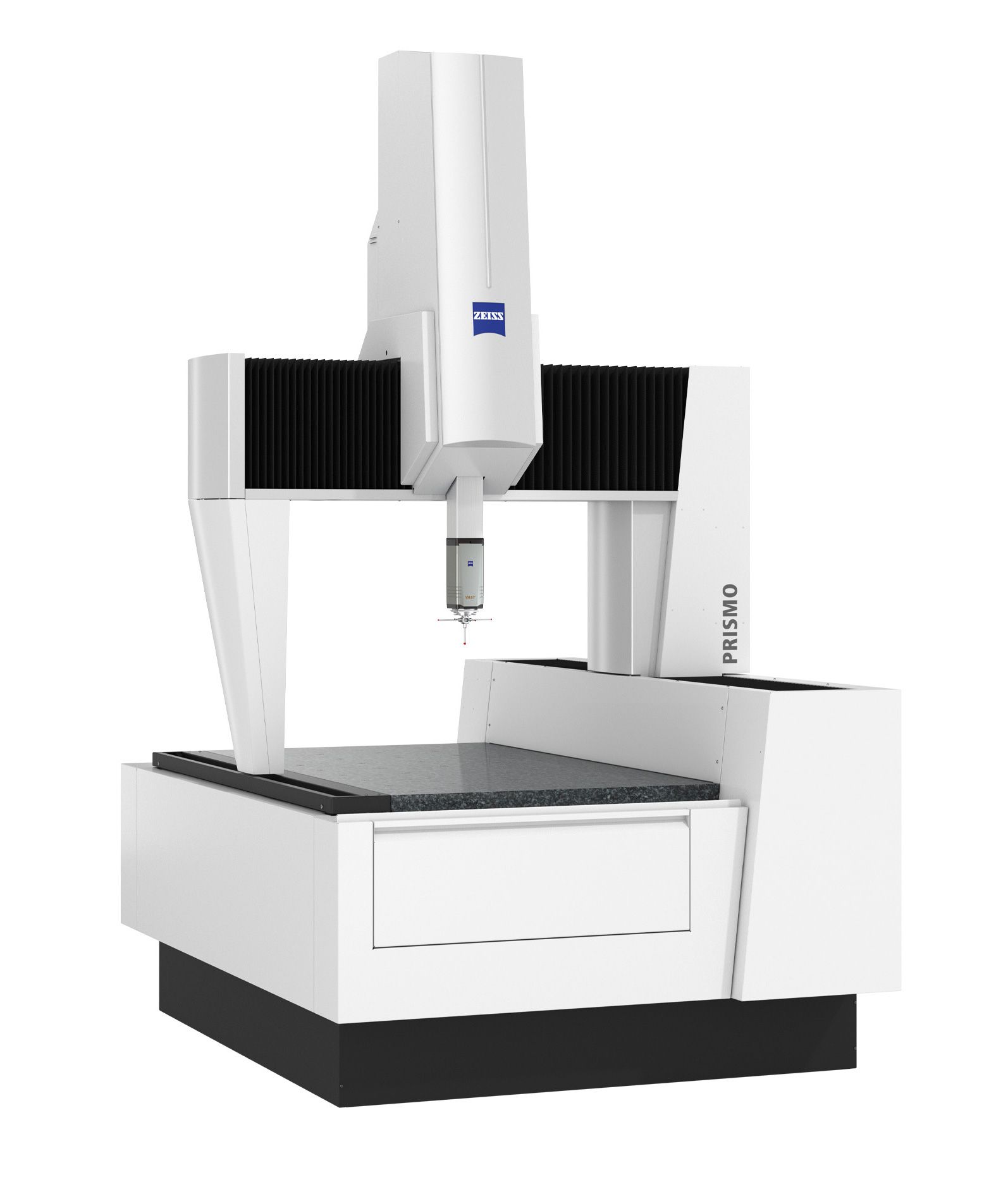

Highly precise coordinate measuring machine: ZEISS PRISMO

ZEISS PRISMO is the reference in precision measurement and meets all ISO quality standards. The CMM guarantees a flawless quality standard throughout your entire value chain and across all production sites. ZEISS PRISMO is equipped with the ZEISS mass technology, allowing you to operate many different ZEISS sensors.

Do you need high precision right where the blades are produced? ZEISS DuraMax is a tactile measuring machine, which was designed to be used on the shop floor. The machine can withstand tough environmental influences. Thanks to its compact dimensions, you can place the system right next to your CNC machines to check turbine blade quality after machining.