ARAMIS Technology

Ready to go

Optical 3D metrology in lightweight construction

Using GOM’s optical 3D measurement technology, researchers at Chemnitz University of Technology, Germany, are able to precisely describe material properties, optimize manufacturing processes, and develop a custom-fit lightweight component for every industrial application. Automobile manufacturers such as BMW benefit from this.

The ARAMIS 3D testing system checks load limits

Using the BMW 7 Series as an example, the researchers designed a technological demonstrator of a roof bow made of fiber-reinforced thermoplastics more well-suited to economical mass production than the thermoset series component. The load limits were investigated on material samples using tensile, comprehensive and shear loads in a temperature range from -30 °C to +85 °C, typical for automotive applications.

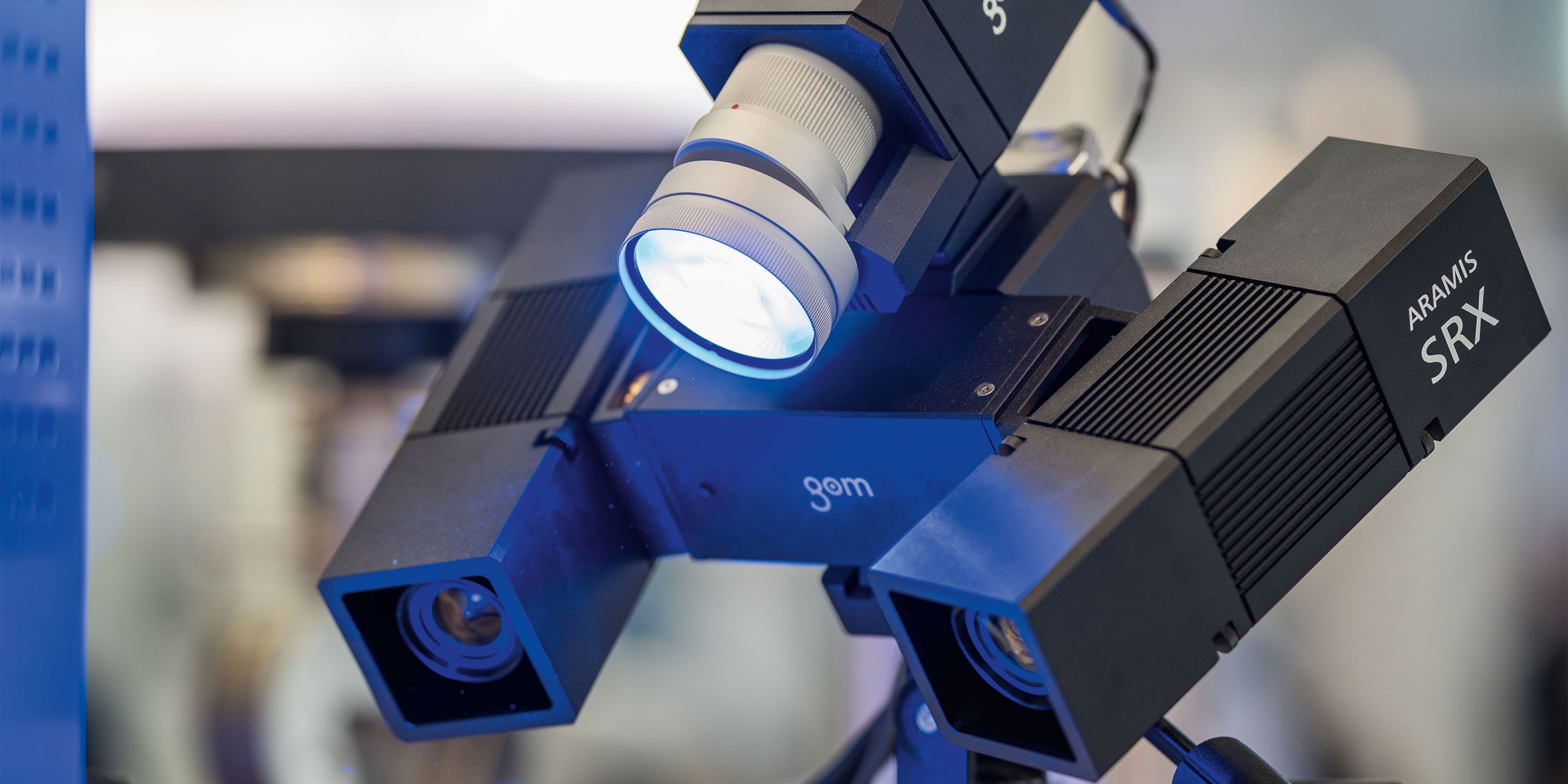

Always on hand: the high-precision ARAMIS measuring sensor from GOM. With up to 2,000 images per second, the stereo camera system records the behavior of the material during the test and provides information on 3D displacements, speed, acceleration, and surface strains. The measuring system offers both surface-based and point-based analysis options.

With ARAMIS, we can test objects of any size and geometry. We analyzed side impact beams, instrument panel supports, a snowboard and, of course, the aforementioned roof bow for the BMW 7 Series.

Flexible measuring area: any geometry, any application

But ARAMIS is not only needed for determining material properties. The researchers also use the mobile deformation and motion sensor for the test bench in the structural tests of the lightweight design components. This is where the scientists benefit from the system’s flexible measuring area.

Shape and dimension analysis with the ATOS 3D scanner

Another piece of the puzzle in the construction process is the 3D shape and dimensional analysis of the lightweight components and tools. To check the production quality, Chemnitz University of Technology relies on GOM’s optical ATOS 3D scanner which, in contrast to tactile systems that measure at specific points, enables precise full-field object digitization.

Norbert Schramm (right) presents a lightweight side impact beam developed by the MERGE team. The molded rib structure increases its stiffness.

Are you interested in more details?

Then read the full application note.

www.gom.com

Learn more about ARAMIS Technology

https://www.gom.com/metrology-systems/aramis.html