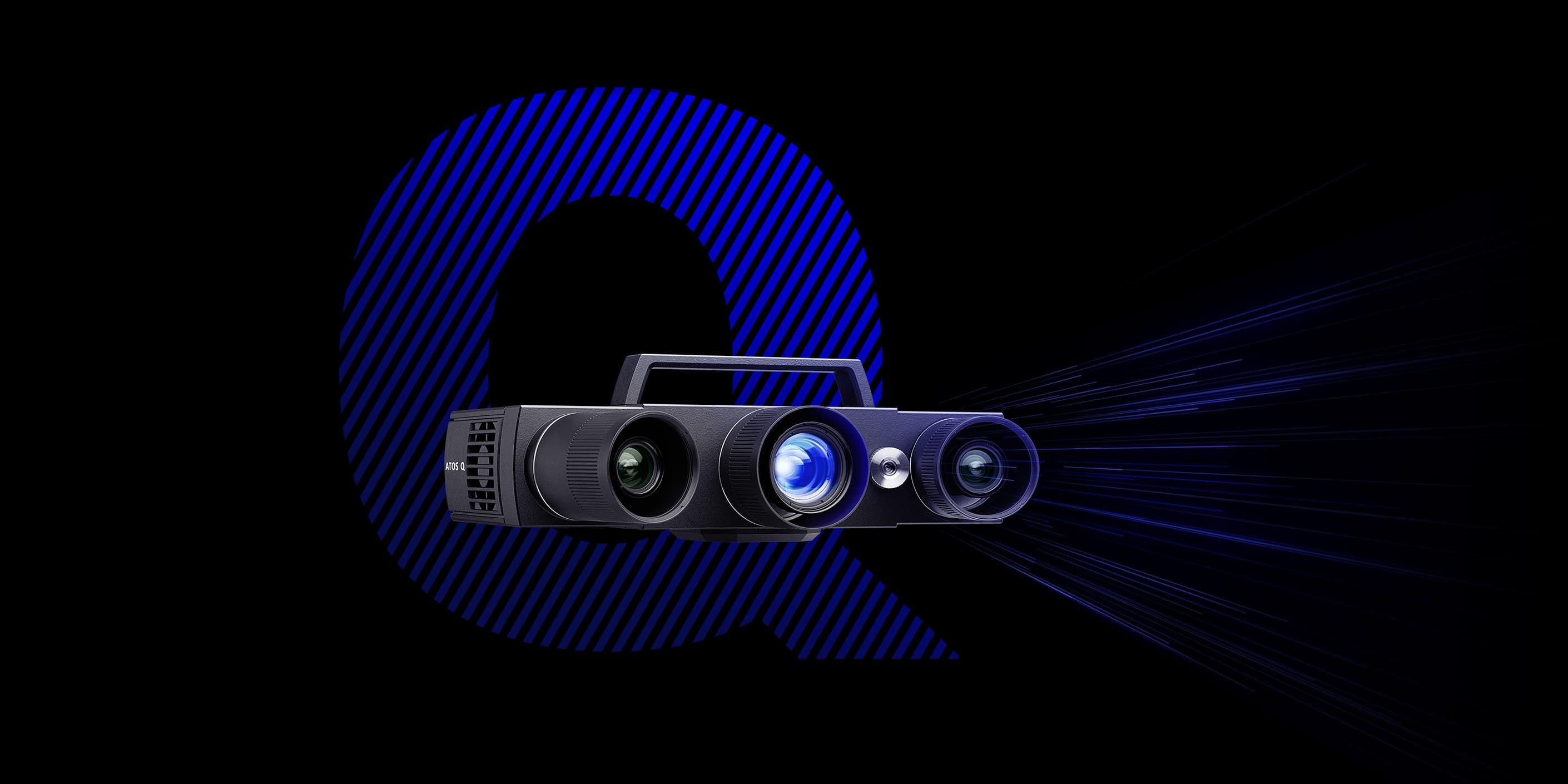

ATOS Q

The small outperformer

GOM’s new ATOS Q is a high-performance 3D scanner for complex inspection tasks. The lightweight and flexible system is equipped with interchangeable lenses for high-precision measurement of small- to medium-sized parts and is powered by the latest GOM software.

In almost all industries, ATOS sensors have established themselves as preferred measuring systems. Their success is based on precise optoelectronics, robust sensor design, and powerful software. Now ATOS Q takes this success story further: the new sensor perfects the triad of design, technology, and performance. The result is a versatile, robust, and compact system with real ATOS DNA.

ATOS design

The systems are specifically developed for industry use and deliver fully traceable results - even under harsh conditions. The optical and electronic systems of the ATOS sensors are dustproof and splashproof, making all models of the product family ideally suited for the move from measuring room to shop floor.

ATOS technology

Producing a complete measurement data set from detailed, full-field 3D coordinates has never been faster and easier. With ATOS systems, a projector casts fringe patterns onto the surface of the component. Two high-resolution cameras record the pattern distortions caused by the object’s contours using the stereo camera principle and send the images to the software.

Blue Light Technology

GOM’s projection technology works with narrow-band, blue LED light. Any interfering ambient light is filtered out during image acquisition, making it possible to obtain precise measurements regardless of the lighting conditions.

Triple Scan Principle

ATOS measuring systems based on the Triple Scan Principle use two high-resolution cameras and a projector to deliver different views of an object, and even a digital twin. This reduces the number of individual scans and provides precise measurement data, even with complex shapes and uncooperative surfaces.

Blue Light Equalizer

A Blue Light Equalizer in ATOS sensors increases the brightness of the light source, resulting in short exposure times. The projection of very narrow fringes per unit area results in precise coverage and capture of complex geometries.

ATOS performance

- Short exposure times, even for uncooperative surfaces, because the Blue Light Equalizer allows high-speed fringe projection.

- Rapid data processing thanks to cameras with fast image processing.

- High data throughput thanks to industrial connectivity with fiber optic cables and robust connectors.