GOM International

New dimension of opportunity

24 years of experience in aluminum die casting have taught the French automotive supplier ZF Fonderie Lorraine a vital lesson: surpassing client expectations requires continuous optimization.

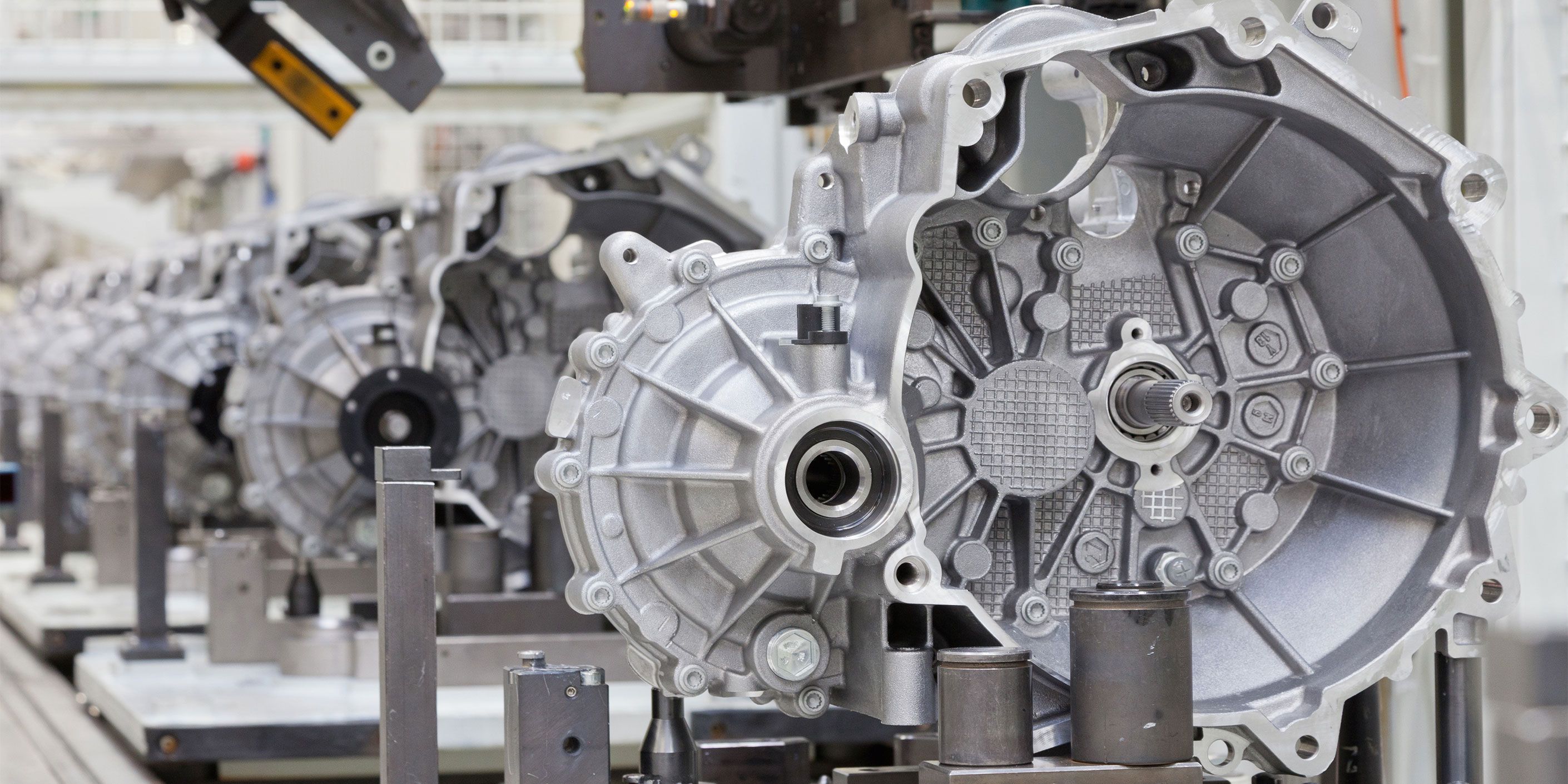

The Grosbliederstroff-based industry leader manufactures complex injection-molded parts in aluminum for automatic gearboxes and engine components, making 17,000 parts every day for prestigious automotive brands such as Audi, BMW and Porsche.

In this business sector, reducing manufacturing reject rates is a critical consideration. After discovering that automated optical 3D metrology would improve its ability to do so, the company sought the ideal tool. They found it with GOM's ATOS Core, installed in an automated measuring cell: the ATOS ScanBox 4105.

The ATOS ScanBox 4105 is an all-in-one system with an easy-to-use automation feature and intuitive interface that ZF Fonderie Lorraine says has made measuring, inspection, and reporting processes quick and easy. Head of Metrology, Peggy Neves-Wackenheim, says that the system enables them to immediately identify any dimensional deviations of parts, resulting in significant time-saving: “We are now able to respond while parts are still blanks and to look ahead even before proceeding with machining. This allows us to not only save time but also money across the entire production process.” As a result, they can undertake new projects while still reducing reject rates.

A full analysis of the part is available after only ten minutes

ATOS systematically supplies a full-field point cloud, which represents the part in its entirety. Having this ability has allowed ZF Fonderie Lorraine to significantly increase and optimize its casting measuring capacities in order to succeed in becoming more responsive to problems. And as a result, to continue exceeding customer expectations.

Learn more about ATOS Core

https://www.gom.com/metrology-systems/atos/atos-core.html

Learn more about ATOS ScanBox 4105

https://www.gom.com/metrology-systems/atos-scanbox/atos-scanbox-series-4.html