Mobile and precise

Mobile measuring made easy

Special measurement environments call for special measuring systems. Wherever they are used – in production, in the workshop or in hard-to-reach areas – measuring systems need to be mobile and robust, while delivering high-precision results. GOM and ZEISS offer versatile 3D scanners for precisely these requirements.

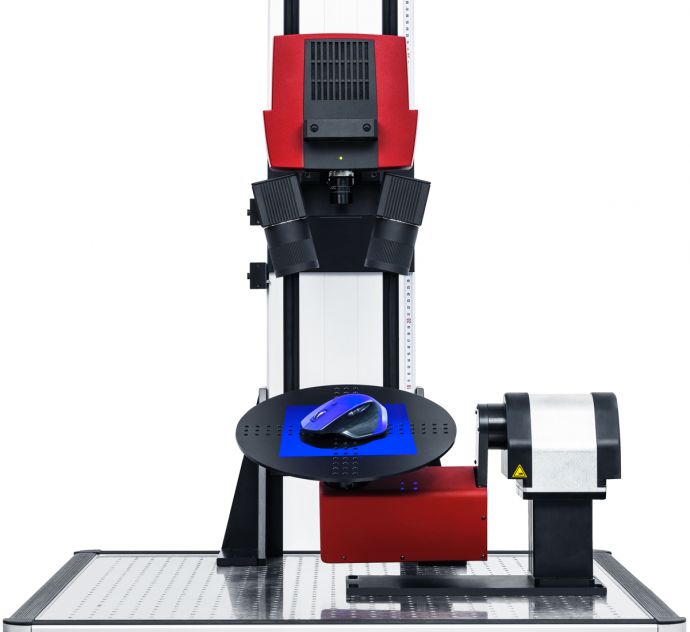

ATOS Compact Scan: professional scanning at an attractive price

ATOS Compact Scan is a mobile 3D scanner for full-field measurement and inspection of parts and tools. The compact measuring system delivers high data quality, with up to 12 million points per scan, and can be used on the production line itself or wherever measurements are needed.

ATOS Compact Scan supports all measuring areas from 40 mm² to 1,200 mm² and is therefore suitable for 3D digitization and analysis of a range of different components and objects. The measuring volume can be scaled up or down at any time using exchangeable camera profiles. With just one sensor head, it is possible to achieve any level of detail and speed. Complex components with areas that are hard to reach using optical technology can be measured with the integrated GOM Touch Probe. Tracking is also possible – for positioning parts in assembly, for instance, or for aligning them before milling.

The complete kit, including 3D scanner and accessories, fits in a suitcase and can be set up and be ready to scan in no time at all. The flexible measuring system is therefore also suitable for digitizing and inspecting large and heavy objects directly in the foundry or workshop.

ZEISS T-SCAN: handheld laser scanner for a range of measuring volumes

The T-SCAN from ZEISS offers fast, intuitive 3D data capture. Thanks to its lightweight, compact housing, the handheld laser scanner allows ergonomic, fatigue-free scanning. In a new development, scanning and inspection now take place in the GOM Inspect software, including a parametric workflow that tracks all process steps. As a result, the software ensures high process reliability for measurement data and reports. GOM Inspect offers not only an intuitive graphic user interface, but also versatile evaluation options for 3D measurement data.

The ZEISS T-SCAN pinpoints its exact position using a tracking system. Since there is no physical connection to the tracker, the user is relatively free to move around. An optical and optional acoustic notification on the handheld scanner means users can see and hear whether the ZEISS T-SCAN has reached the optimum distance from the part. Depending on the model, the maximum measuring volume is 20 m3.

Working hand in hand: Thanks to a seamless shared workflow, ZEISS T-SCAN hardware and GOM Inspect Suite software deliver fully traceable measurement results.